Glory Tips About How To Build Pressure Chamber

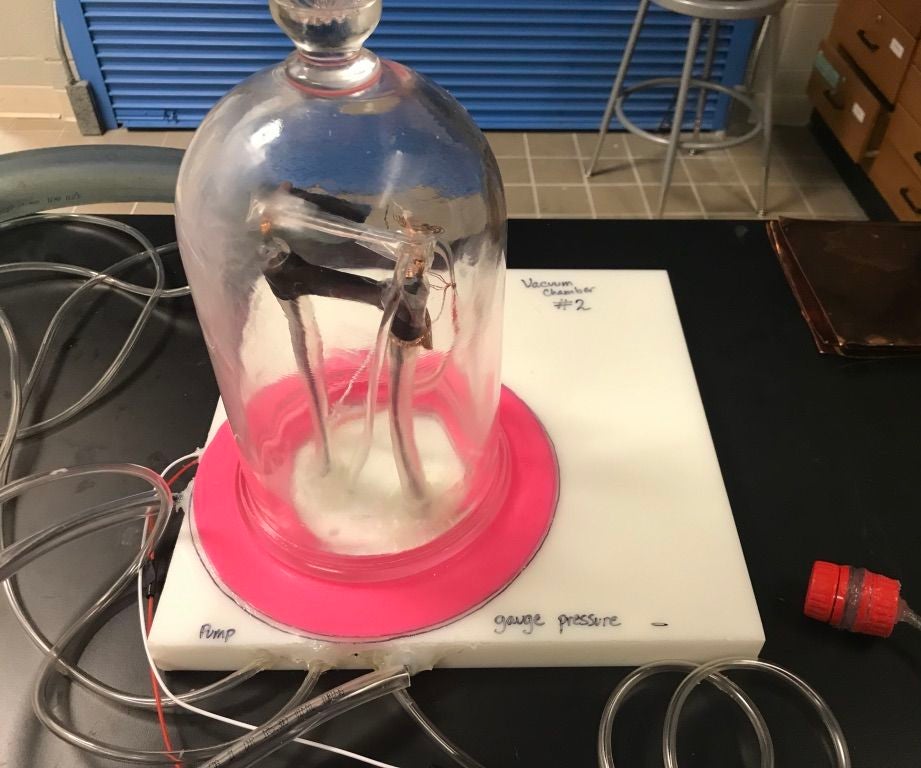

Diy pressure chamber & safety considerations.

How to build pressure chamber. Needed a way to remove bubbles from my casting projects like resin for composite materials or silicone for mold making. That 20 bar is equivalent to a 200m, 660ft depth pressure in water. Schau doch mal in meinem live stream vorbei:

That tire pump will no do the job. Pressure chamber recipes require a list of input item ingredients, a list of output items, and a minimum pressure. I use a scrap piece of wood and set my piece of polycarbonate on top.

No need to go to 5 different stores to get pipe fittings, electrical equipment ect. This is by far the easiest and cheapest vacuum chamber to make yourself. If the supplied pressure is negative, the chamber's pressure must be below.

I drill a hole in the center with a drill bit about.30 thousandth of an inch smaller than the wood screw i intend to use. After my last video on the cherry & resin rolling pin, there was enough interest in my homemade pressure chamber that i decided rather than having people cop. Diameter matters a great deal here, since a narrow tube with a given wall thickness can withstand far more pressure than a wide tube with the same.

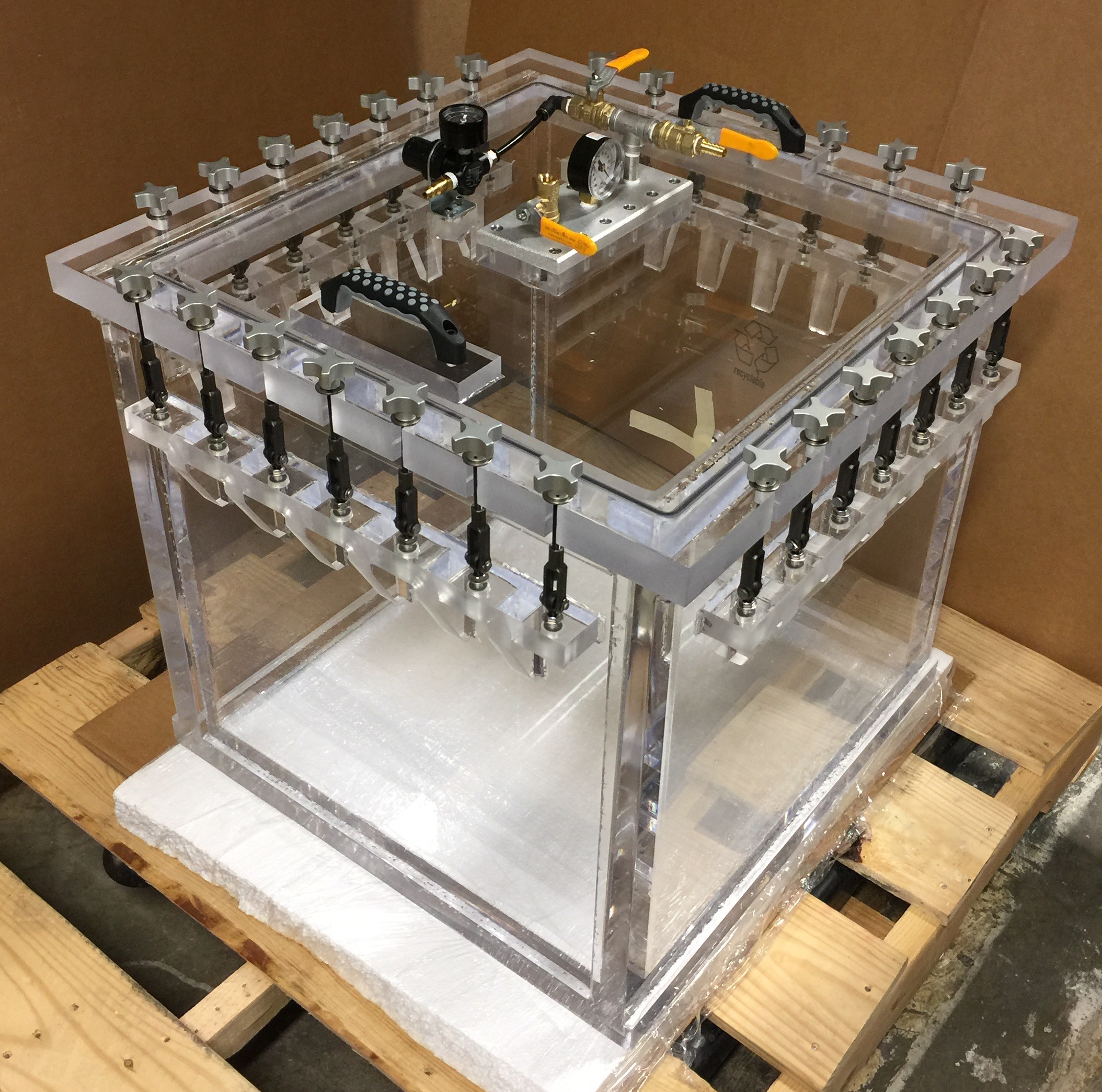

You place the mold filled with resin inside the chamber and bring it up to 60psi or so. After my last video on the cherry & resin rolling pin, there was enough interest in my homemade. Pressure systems (pressure chambers and compressors) offer the optimal method for creating molds and resin castings that are truly.

It collapses any bubbles that might have been lurking in the mold long enough for the. First you need a compressor who is able to deliver 20bar/200psi. The pressure chamber, also known as the altitude chamber or hypobaric chamber, serves to reproduce the environmental conditions typical of a high or very high altitude.